FGD Butterfly Valve Applications:

Baigang valve groupproduction and sales of D371X FGD Butterfly Valve desulfurization butterfly valve can be widely used in water and electricity, water, building, air conditioning, petroleum, chemical, food, medicine, textile, paper making, water supply and drainage and other fluid on the pipeline as the adjusting and intercepting use, and can be borrowed by the material changes, to apply to different media such as water, gas, oil, applicable temperature - 20 ~ 80 ℃.By replacing the disc sealing ring, O-ring, butterfly plate, shaft and other materials, can be used in a variety of media and different temperatures.The valve automatic control is equipped with high quality electric actuator or double acting pneumatic actuator, which can realize the double opening and closing function of automatic and manual.

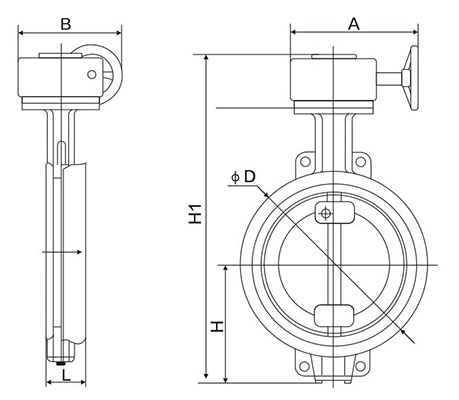

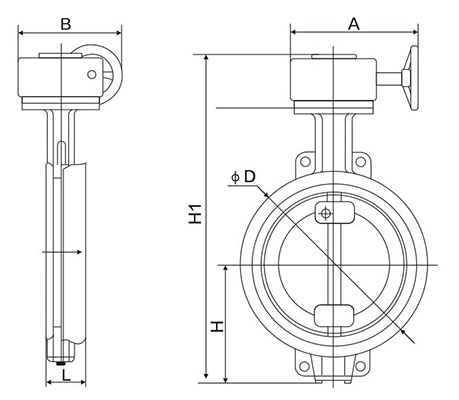

FGD Butterfly Valve structure features:

The

main structure is composed of valve body, valve disc, valve seat, valve

stem and transmission operation mechanism and other components. The

valve seat adopts detachable structure, and according to the physical

and chemical characteristics of different media, the corresponding high

temperature resistance, low temperature resistance, corrosion resistance

, Light, anti-aging materials.

Valve ductile iron shell inside

and outside the surface can be high temperature electrostatic spraying

epoxy powder coating, the coating has high corrosion resistance, and

ductile iron matrix has a very high bonding strength, coating degree of

0.2-0.5mm.

1, the use of neutral structure without eccentric

design, with significant characteristics of low operating torque,

electric device configuration when the economy is significant;

2, a reasonable design, compact structure, easy installation and removal, easy maintenance;

3, , Butterfly plate circumferential sealing surface precision

machining to a higher finish, the friction coefficient of the rubber

valve seat is very low, longer valve life;

4, valve plate sealing surface flow characteristics of a linear state,

with a smaller flow resistance Coefficient, valve flow resistance is

small;

5, a unique design of the molded rubber valve seat has excellent

balance and support, effectively avoid the force caused by the rubber

damage, the valve at the fully closed position, the rubber in the best

to maintain the compressed state zero leakage;

6, the two-port valve sealing surface projecting rubber flange ductile

iron, no additional valve rubber gasket installed in the pipe

7, the valve operating mechanism flexible choice;

8, valve attractive appearance resistance Corrosive.

FGD Butterfly Valve main form of connection size

unit: mm

unit: mm

|

DN

|

L

|

H

|

HO

|

A

|

B

|

0.6MPa

|

1.0MPa

|

1.6MPa

|

|

DO

|

nd

|

DO

|

nd

|

DO

|

nd

|

|

50

|

43

|

63

|

306

|

180

|

200

|

110

|

4-14

|

125

|

4-18

|

125

|

4-18

|

|

65

|

46

|

70

|

321

|

180

|

200

|

130

|

4-14

|

145

|

4-18

|

145

|

4-18

|

|

80

|

46

|

83

|

346

|

180

|

200

|

150

|

4-18

|

160

|

8-18

|

160

|

8-18

|

|

100

|

52

|

105

|

387

|

180

|

200

|

170

|

4-18

|

180

|

8-18

|

180

|

8-18

|

|

125

|

56

|

115

|

411

|

180

|

200

|

200

|

8-18

|

210

|

8-18

|

210

|

8-18

|

|

150

|

56

|

137

|

447

|

270

|

280

|

225

|

8-18

|

240

|

8-22

|

240

|

8-22

|

|

200

|

60

|

164

|

572

|

270

|

280

|

280

|

8-18

|

295

|

8-22

|

295

|

8-22

|

|

250

|

68

|

206

|

646

|

270

|

280

|

335

|

12-18

|

350

|

12-22

|

355

|

12-26

|

|

300

|

78

|

230

|

738

|

380

|

420

|

395

|

12-22

|

400

|

12-22

|

410

|

12-26

|

|

350

|

78

|

248

|

761

|

380

|

420

|

445

|

12-22

|

460

|

16-22

|

470

|

16-26

|

|

400

|

102

|

289

|

877

|

450

|

470

|

495

|

16-22

|

515

|

16-26

|

525

|

16-30

|

|

450

|

114

|

320

|

938

|

480

|

490

|

550

|

16-22

|

565

|

20-26

|

585

|

20-30

|

|

500

|

127

|

343

|

993

|

480

|

490

|

600

|

20-22

|

620

|

20-26

|

650

|

20-33

|

|

600

|

154

|

413

|

1131

|

480

|

490

|

705

|

20-26

|

725

|

20-30

|

770

|

20-36

|

|

700

|

165

|

478

|

1476

|

640

|

660

|

810

|

24-26

|

840

|

24-30

|

840

|

24-36

|

|

800

|

190

|

525

|

1533

|

640

|

660

|

920

|

24-30

|

950

|

24-33

|

950

|

24-39

|

|

900

|

203

|

585

|

1655

|

750

|

860

|

1020

|

24-30

|

1050

|

28-33

|

1050

|

38-39

|

|

1000

|

216

|

640

|

1765

|

850

|

900

|

1120

|

28-30

|

1160

|

28-36

|

1170

|

28-42

|

|

1200

|

254

|

755

|

1995

|

850

|

900

|

1340

|

32-33

|

1380

|

32-39

|

1390

|

32-48

|

unit: mm

unit: mm